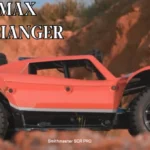

We are Smithmaster Co., Ltd., a company that has developed and is currently exporting the RC car “Smithmaster” to countries such as the United States, Canada, and France.

Today, we would like to introduce a video review by a YouTuber named “Mattew SR” about 12s runaround continues from previous posting

Table of Contents

Tips for Stability and Performance: How to Maintain Your W5 Machine Effectively?

When you’re working with machines like the W5, it’s super important to keep an eye on the details right from the get-go. You want to make sure everything is fitted correctly—tight enough to stay put, but not so much that it causes strain. The way you put it all together is pretty standard, similar to the W5 setup, but don’t forget those unique bits like the spacers that help with alignment. Luckily, there’s no wobbling in the assembly, which is a major win for stability. A small socket and a light tap with a hammer can be your best friends here for getting that snug fit. Plus, there’s a nifty mark on the cardan pin that keeps it in place, and using a bit of abrasivity when reinstalling can really amp up its grip. All in all, if your front train is running smoothly, you’re on the right track with your assembly process!.

How to Fix a Loose Screw in Differential Support?

So, let’s chat about a little hiccup with the screw in the central differential support. The deal here is that the thread inside isn’t stripped but has somehow gotten loose, making it a pain to release the screw since it gets wedged against the chassis. The fix? Our speaker plans to whip out some two-component glue, but with a careful touch to avoid any overflow—because we definitely don’t want that ruining the screw reinsertion. They’ve even had success with this adhesive on different jobs, including cutlery, so it’s safe to say it should hold up pretty well..

How to Handle DIF Central Parts?

Setting up DIF Central Parts might look a bit daunting at first, but don’t worry—you’ll get the hang of it! I took apart the other section of the central DIF and, with some pliers, I managed to pull it out without too much hassle. There’s a noticeable damage to the threading at the top, but I got everything out in the end. I haven’t dived into the central DI just yet, but I’m planning to do that live with you all. Oh, and just a quick heads up—the gear has 60 teeth. Since we’re at 64 on MCD, it’s crucial to check out the rest of the system for a solid comparison..

What are the concerns about machine performance?

Back in 1960, you’d find that the equivalent measurement was about 2264 in those terms. When I first grabbed that machine, I’ll be honest, I wasn’t feeling too great about it. I hadn’t seen any similar ones over in France, and frankly, the only videos I found showed machines crawling at 3 km/h. On top of that, JP didn’t exactly fill me with confidence; he mentioned that after just 3 or 4 hours of use, they had issues with the central DIF. So, in the end, how well the machine performs really depends on how it’s used, and there’s always a chance you might stumble upon a defective unit or some assembly hiccup..

Thank you for reading our contents!

If you’re interested in Smithmaster’s RC cars, please check out other articles as well!For those interested in owning one, a quick visit to the Smithmaster website through the link provided can get you started : https://smithmaster.net/

1 thought on “SCR Pro Upgrade Insights_5TH Tips for Stability and Performance”