We are Smithmaster Co., Ltd., a company that has developed and is currently exporting the RC car “Smithmaster” to countries such as the United States, Canada, and France.

Today, we would like to introduce a video review by a YouTuber SMITHMASTER SCR PRO 12s continues from previous posting

Table of Contents

Challenges and Insights : Observations on Gear Issues and Adjustments

The author experienced pinion gear loss, highlighting difficulties with gear setup. The pinion sourced from AliExpress was too thick, causing compatibility issues with the motor shaft. Attempts to sand down the pinion’s thickness have been partially successful, though adjustments are still required as it tends to loosen. Despite these challenges, gear refits have improved performance.

Performance Comparisons and Observations

Preference is shown for the Hoby Wing Max 5 G2 over the R5 V12 Pro Leopard, finding it superior for this setup. With Hoby Wing having a minimum of 650 kV, the current setup requires a smaller pinion compared to the previous 530 kV. Static tests with MCD and the new combo demonstrated smooth acceleration, thanks to sensor capabilities. The speaker finds the current combo performs better off-road, even with some precision loss.

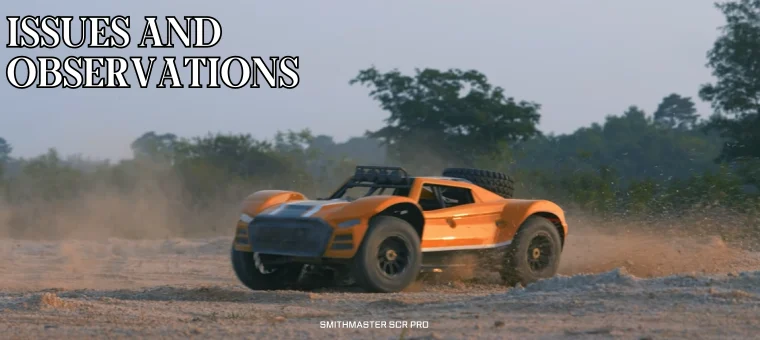

Issues and Observations During SCR PRO Testing

During the testing phase of the SCR PRO, a notable metallic noise was observed, particularly during landings, raising concerns about the equipment’s integrity. Issues with the shocks were also identified, as the chassis made contact with the ground, which might lead to mechanical stress. Electrical problems are affecting performance, notably during gear changes and motor engagement, while temperature readings indicate overheating in certain components, such as the driveshaft, which could result in significant damage if not addressed.

Observations on Equipment Performance

The speaker reports a prominent metallic noise during operation, especially noticeable upon landing. Such findings raise concerns that the shock absorbers may not effectively manage large jumps, as evidenced by the chassis bottoming out. There’s also apprehension regarding the chassis height, which still leaves a 1 cm clearance from the ground, causing potential issues for future runs. Further research into proper gear setups is planned, highlighting the need for an 8 to 10 mm spacer.

Addressing Mechanical Issues and Performance Challenges

Seeking a robust solution to minimize downtime from mechanical failures, the speaker emphasizes the importance of operational reliability. An existing issue noted is a cut-off during use, indicating performance inconsistency. Acknowledgement is made of possible faults in the electronic components contributing to operational problems. Overall, significant concerns exist regarding mechanical functionality, focusing on the shock absorbers and the potential for loosened or worn-out parts.

Performance Insights from SCR PRO Testing

The initial test run lasted 11 minutes, but strange noises during the second run led to a halt. The drivetrain pin exhibited signs of overheating, indicating excessive friction, which could pose problems. Concerns were also raised about the electronic setup, attributed to using incompatible components and issues arising from tightening that affect adhesive contacts. Despite these challenges, the tester found the vehicle’s performance and aesthetics enjoyable and plans future tests with different wheels and settings.

Monitoring Component Temperatures for Performance Insight

Particular attention is given to the temperature of the driveshaft, underscoring its impact on equipment health. A notable decrease in pinion force suggests potential performance issues. Wear traces on the pinion, with temperatures around 80°C, indicate possible overheating or prolonged use. However, additional measurements showing motor temperatures below 60°C suggest relatively acceptable operating conditions, even under intensive runs.

Battery Performance and Conclusions

Battery analysis reveals a remaining charge of 38%, indicating a relatively uniform discharge. The discussion on battery performance concludes the testing phase, summarizing previous evaluations. The insights gathered highlight the effectiveness of current settings and the necessity for continuous monitoring. These findings emphasize understanding battery performance as crucial in optimizing RC setups.

Thank you for reading our contents!

If you’re interested in Smithmaster’s RC cars, please check out other articles as well!For those interested in owning one, a quick visit to the Smithmaster website through the link provided can get you started : https://smithmaster.net/